How Its Made- FUSELAGE

The outline for the side walls of fuselage is traced onto the balsa sheet and cut out as shown above.........

All the formers are glued perfectly perpendicular onto any one of the side walls in the marked places..........

The other side wall is stuck onto the formers, and at the tail to the other side wall as shown above..............

The space between the formers F1 and F2 is reinforced by gluing 2cm wide balsa strip on the belly edge and a 1cm wide balsa strip on the wing mount of the fuselage .....

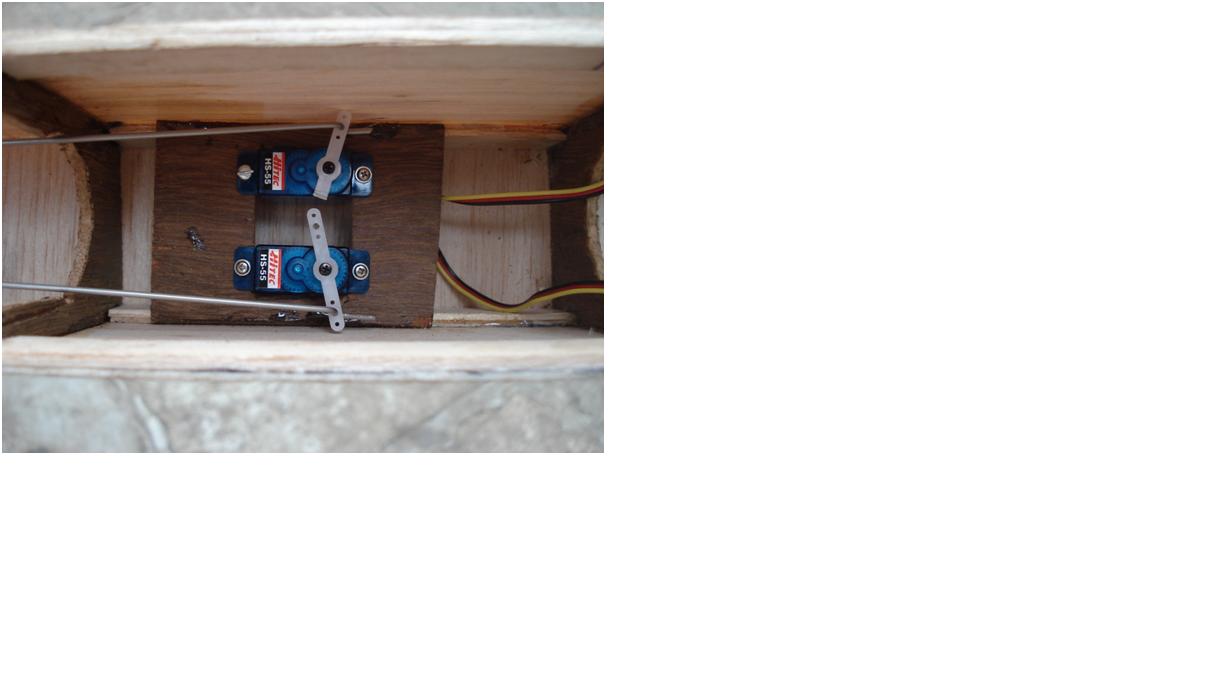

The top and bottom of the fuselage is sheeted (except the place where wing covers the fuselage) and a servo tray is cut for the servos and glued on the edge of the 2cm wide strip between formers F1 and F2....

The control rod( pushrod ) is made by attaching cycle spoke on a wooden dowel as shown......

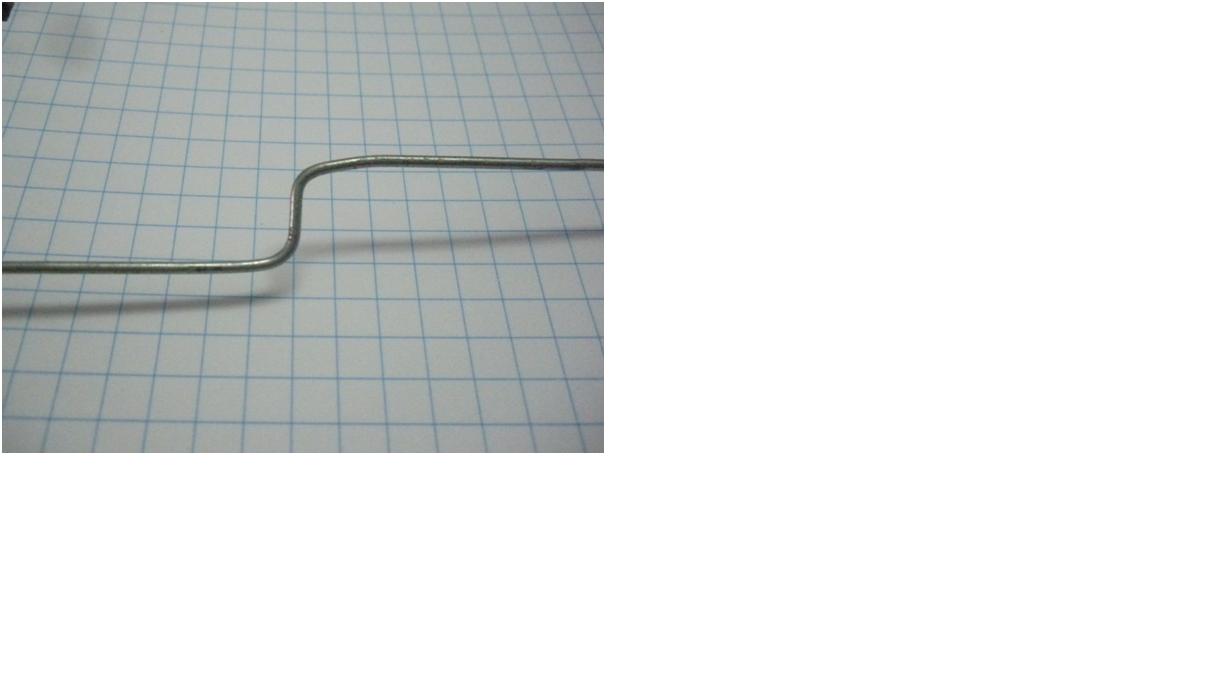

Z bends such as this are made on control rods by measuring appropriate distances..........

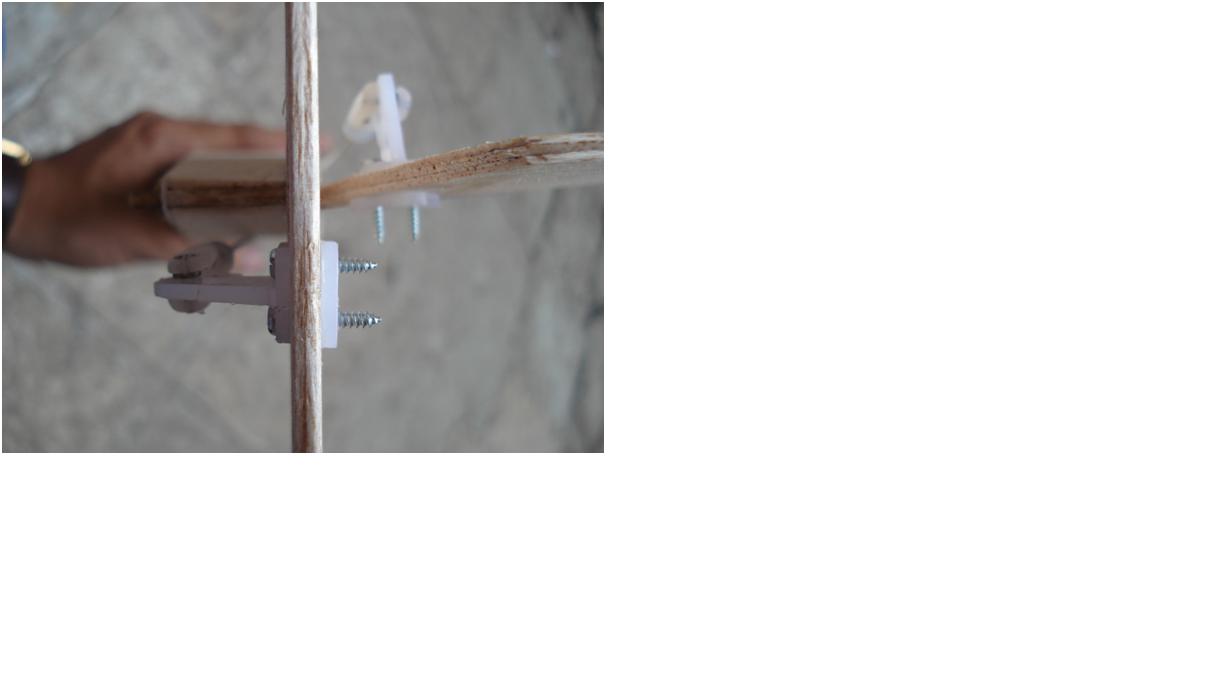

The tail plane sections(vertical stabilizer , fin, rudder and elevator) are made according to the given dimensions and the rudder and elevator are stuck onto the fin and horizontal stabilizer respectively using ribbon hinges. The rudder and elevator horns as screwed on ...........

The tail plane is stuck on the fuselage as shown above.................